Ozone in DWTP

Ozone in Drinking Water Treatment Plant

Use of ozone in DWTP

Ozone is an excellent ally in public drinking water treatment stations (DWTP). When diluted in water, it oxidizes heavy metals, toxins, pesticides, phytosanitary products, reduces organic load, COD, BOD, TOC, turbidity, SS, SD, odour, taste, enhances coagulation and flocculation, improving settling. Increases filter performance, lengthens its useful life, and reduces the number of washes.

It is a super disinfectant that leaves no residue, reduces chlorine consumption, and prevents the appearance of trihalomethanes and other organochlorine compounds. In addition, the ozone is generated in situ, it does not need to be stored, transported or managed, the system works fully automatically. Applying ozone + activated carbon in your drinking water treatment plant is a guarantee of success.

Optimize your DWTP by applying ozone and improve water quality.

Ozone allows for a reduction in chemical consumption

It is generated on-site, eliminating the need to store or transport chemicals

Ozone contributes to sustainability and reduces the carbon footprint

The system is automated, so no labor is required for its application

Problems with the quality of the DWTP water?

Phases of Ozone in an DWTP

In PRE phase

Ozone improves the effectiveness of coagulation and flocculation in public drinking water treatment plants, enhancing sedimentation. It oxidizes heavy metals and reduces COD, BOD, turbidity, SS, SD, color, odor, etc. In this phase, disinfection processes begin.

In INTER phase

Ozone improves filtration performance in the WTP, extends the life of the filters, and reduces the frequency of cleaning, thus decreasing reject. Ozone is applied between the activated carbon filtration stage, achieving total water disinfection and enhancing the subsequent absorption process.

In POST phase

Ozone, a powerful disinfectant used in the WTP, is highly effective in eliminating all types of microorganisms in very short times, without generating chloramines or organochlorine compounds. In this phase, ozone is applied to ensure disinfection during the distribution phase.

Effects of Ozone in an DWTP

1. Oxidizes heavy metals

Ozone oxidizes heavy metals, as well as metals like iron and manganese, making them insoluble, which facilitates their settling or retention in filters. This is why its use is common in a PRE phase, injecting ozone at the head of the WTP.

2. Enhances flocculation and coagulation

Ozone itself already has a flocculation and coagulation effect due to the polarization of water as the Redox potential increases. Additionally, it enhances the effect of other flocculants and coagulants, maximizing the aggregation of organic and inorganic material.

3. Improve filtering performance

With an optimized decantation phase, filters handle a lower load, resulting in fewer backwashes and a longer lifespan. Finally, ozonation generates molecules with a better average molecular weight, enhancing absorption in activated carbon filters.

4. Powerful disinfection

Ozone eliminates all types of microorganisms, such as viruses, bacteria, fungi, and molds, at low concentrations and short contact times. Additionally, it has a low residual effect.

5. Improves odor and taste

Chlorination in the presence of organic matter generates organochlorine compounds that, in addition to being harmful, impart an unpleasant taste and odor to the consumer. The most effective method is the combination of ozonation + filtration over activated carbon (O3+GAC).

6. Reduces the use of chlorine and chloramines

Better-treated water with a lower organic load will require fewer oxidants to maintain optimal disinfection levels. Therefore, if you use ozone in your ETAP, you will consume less chlorine.

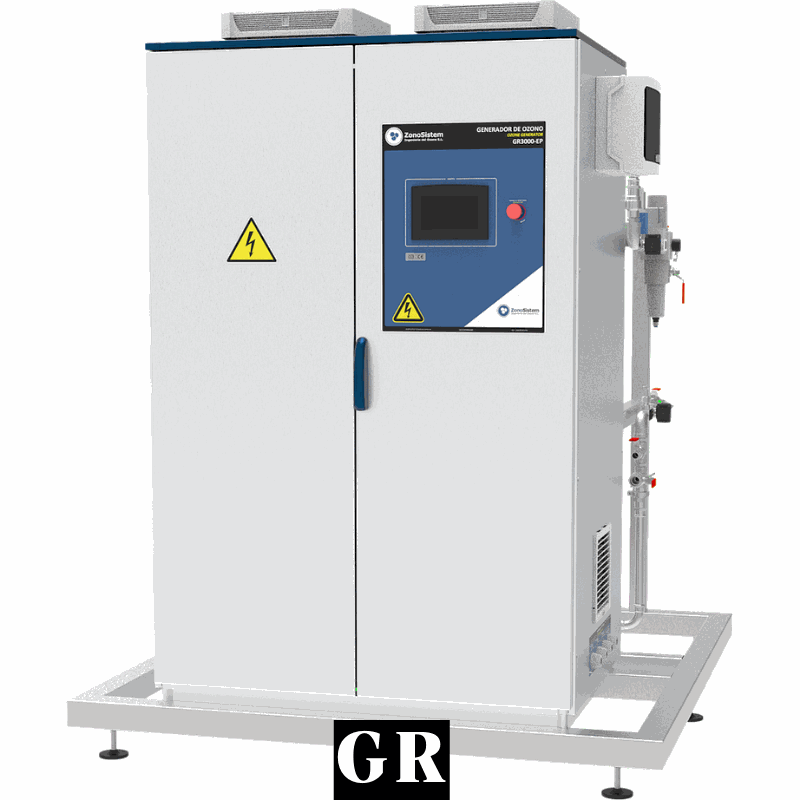

What type of ozone generator do I need?.

Next, we will show you the ranges of ozone generators available for DWTP.

|

|

| |

| Recommendations | Ozone equipment from 80 to 5.000 gO3/h For LOX feeding, liquid oxygen. | Ozone equipment from 5 to 150 kgO3/h For LOX feeding, liquid oxygen. | Ozone Equipment from 80 to 500 gO3/h Includes complete air unit (Compressor + PSA) |

| Included Equipment | Generation Ferrule, Borosilicate Dielectric. Water Cooled Generator. Transformer and electrical panel. With Automatic Power Control. With Recipe manager by PLC. With Leak Sensor. | Generation Ferrule. Borosilicate or Ceramic Dielectric. Water Cooled Generator. Transformer and electrical panel. With Automatic Power Control. With Recipe manager by PLC. With Leak Sensor. | Generation Ferrule, Borosilicate Dielectric Water-Cooled Generator. Transformer and electrical panel. With Automatic Power control. With Recipe manager via PLC. With Leak Sensor. With Oxygen Compressor and Concentrator. With Integrated Cooler. |

| Optional Equipment | Ozone gas meter. Cooling system. Dosing system. Ozone destruction system. Sub-over valves. | Ozone gas meter. Cooling system. Dosing system. Ozone destruction system. Sub-over valves. | Ozone gas meter. Ozone destruction system. Sub-over valves. |

| Ozone Concentration | 150 gO3/m3 | 150 gO3/m3 | 150 gO3/m3 |

| Ozone Production | From 80 to 5.000 gO3/h | From 5 to 150 kgO3/h | From 80 ato 500 gO3/h |

| Working Conditions | 1 bar | 1 bar | 1 bar |

1. What is the difference between the ranges?

The GR and GRV ozone generator ranges are designed to be powered with LOX oxygen. They are industrial-grade, robust units with high ozone concentration, designed and manufactured with care to operate 24/7. The GR range covers up to 1 kg O₃/h, featuring ceramic dielectric technology, while the GRV range is intended for higher production, up to 40 kg O₃/h. On the other hand, the GRZO range differs from the other two because it comes with an integrated compressor and oxygen concentrator, so it doesn't require LOX oxygen. It is an autonomous unit that only needs electricity. It is also an industrial-grade system with high performance and efficiency.

2. Which range do you recommend?

The first thing is to calculate the amount of ozone you need. If you need more than 1Kg or 3/h, you will have to select the GRV range. For productions less than 1KgO3/h, you have the GRZO version, with compressor and oxygen concentrator, and if you prefer to work with LOX oxygen supply, you have the GR range. I recommend using the GRZO range whenever possible, it is a bit more expensive but you avoid the costs of LOX oxygen.

3. How much ozone do i need?

Generally, doses between 2 and 3 ppm of ozone are applied to the plant's total flow.

Examples of Ozone in DWTP

Ozone for DWTP in Mexico. DWTP Santacruz.

Ozone for DWTP in Galicia. DWTP P.I Sabón.

Ozone for DWTP in Mexico. DWTP Calderas.

Ozone for DWTP in Huelva. DWTP Conquero.

Ozone for DWTP in Almeria. DWTP Bajo Almanzora.

Ozone for DWTP in Extremadura. DWTP Llerena.