Ozone in cold rooms and conservation

Ozone to sanitize and eliminate bad odors in cold rooms

Use of ozone in cold rooms

Advantages and benefits of the use of ozone in cold rooms

Ozone is used in cold rooms to disinfect the environment and surfaces and eliminate bad odors. Ozone is a gas that quickly and efficiently eliminates viruses, bacteria, fungi and molds, from the environment and surfaces of the cold room, refrigeration or storage of perishable products, as well as bad odors. The ozone generator is responsible for generating ozone in situ, and injecting it into the refrigerated chamber instantly. The ozone system works automatically, it is easy to install.

These advantages make ozone a powerful tool to sanitize refrigerated rooms automatically and easily, and without using labor. In the case of preserving fruits and vegetables, ozone also degrades ethylene, preventing accelerated ripening of fruits and vegetables.

Ozone to improve the conservation of vegetables, fruits, meats, fish in refrigerated chambers

Ozone reduces the consumption of chemical products

Ozone is generated on-site, it does not need to store or transport chemicals

Ozone does not leave residues, it is respectful with the environment

The system is automated, you do not need manpower to apply it

Problems with the sanitization of cold rooms?

Advantages of using Ozone in cold rooms

Elimina hongos, bacterias, mohos y esporas

A cold room ozone treatment is a disinfection process that uses ozone to kill bacteria, viruses, and other pathogens present in the air and on surfaces in a cold room. Ozone is a highly reactive form of oxygen that acts as a powerful oxidant and disinfectant, and is capable of destroying harmful microorganisms.

Environmental disinfection of the cold room

Ozone treatment has several advantages over other disinfection methods, such as the use of chemicals. Ozone leaves no chemical residue, requires no downtime, and has no harmful effects on food. Additionally, ozone is an effective disinfection agent against a wide variety of pathogens, including bacteria, viruses, fungi, and spores.

Problems with odors in the cold room

During the cold room ozone treatment process, a controlled amount of ozone is introduced into the cold room through an ozone generator. Ozone is evenly distributed throughout the cold room, including corners and hard-to-reach areas, completely eliminating odors

Without labor, automatic

The system generates ozone and automatically introduces a controlled amount of ozone into the chamber through an ozone generator, without the need to apply labor in the process. The equipment only needs a point of light

No chemical storage

Ozone cannot be transported or stored, it is generated on site, and it is applied instantly, so it is not necessary to store and manage chemical products, it avoids transport and reduces the carbon footprint.

Biocide recognized by the ECHA

Ozone is on the list of biocides by the European Chemical Agency and ZonoSistem has all the necessary legalization documentation to be able to apply ozone in its process.

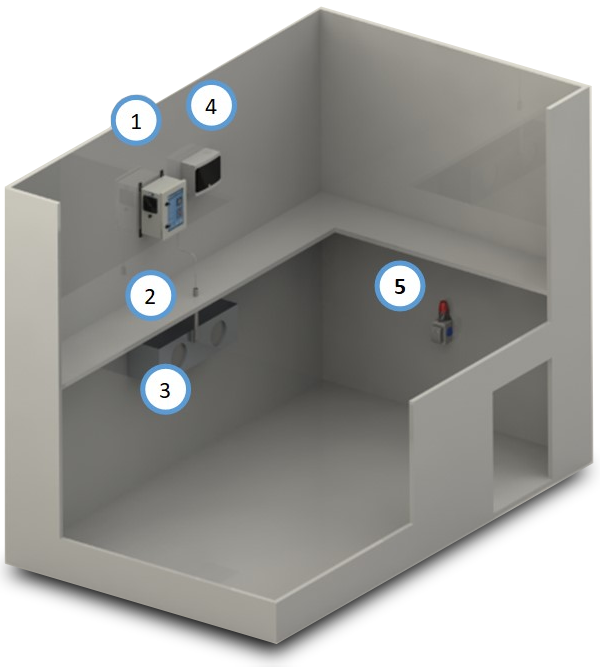

Installation of an ozone system in individual chamber

installation diagram

We deliver installation manual, electrical and pneumatic connection.

1. Ozone Generator

Responsible for producing ozone from ambient air.

2. Injector

Accessories to inject ozone into the chamber, generally in front of the evaporator.

3.Trampa de Condensados

To collect condensate and prevent it from falling on the floor or on top of food.

4. Controlador CRTL45

With daily time programmer and manually adjustable CAP.

5. Ozone Sensor

Optional - to regulate the equipment automatically based on the ozone existing in the chamber.

refrigerated dryer

Opcional. Para instalar el generador de ozono en ambientes con humedad superior al 70%.

Available models

Select the ozone generators you need based on the volume of the cold room you want to cover.

| Generador de ozono | GZ1-E | GZ2-E | GZ3-E | GZ7-E |

| Chamber volume | < 250 m3 | < 500 m3 | < 750 m3 | < 1.750 m3 |

| ozone production | 1 gO3/h | 2 gO3/h | 3 gO3/h | 7 gO3/h |

| Applied ozone rate | 4 ppm | 4 ppm | 4 ppm | 4 ppm |

| Caudal de aire | 15 lpm | 15 lpm | 50 lpm | 200 gO3/h |

| Consumo | 80 W | 130 W | 160 W | 500 W |

| Size A x B x C cm | 31 x 24 x 16 | 40 x 30 x 20 | 40 x 30 x 20 | 80 x 40 x 25 |

| Tamaño | 200 gO3/h | 200 gO3/h | 200 gO3/h | 200 gO3/h |

Description

With air-cooled borosilicate dielectric ozone generation technology. To work in normal conditions of ambient temperature 5-35°C and Relative Humidity <70%. All models are connected to 230v, 50 hz and have an ozone outlet for an 8mm Ext.

The equipment requires a maintenance plan.

Design and control

ZonoSistem has designed an ozone system for the disinfection of cold rooms with ozone, using the GZ range.

With the possibility of manual or automatic control by environmental ozone probes and PLC with touch screen.

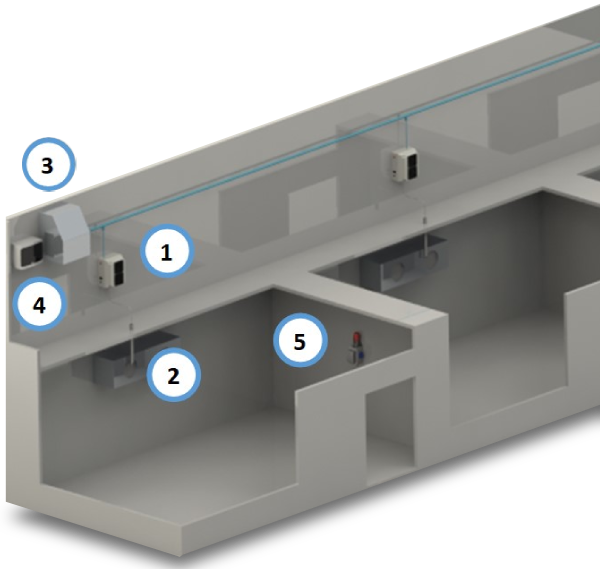

Installation of a multi-chamber ozone system

installation diagram

We deliver installation manual, electrical and pneumatic connection.

1. Ozone Generator

Responsible for producing ozone from ambient air.

2. Injector

Accessories to inject ozone into the chamber, generally in front of the evaporator.

3. Air Unit

It prepares the air and channels it to the ozone generators.

4. CRTL55 controller or PLC Touch screen

With daily time programmer and manually adjustable CAP.

5. Ozone Sensor

Optional - to regulate the equipment automatically based on the ozone existing in the chamber.

refrigerated dryer

To dry the compressed air line.

Available models

Select the ozone generators you need depending on the Volume of the cold rooms you want to cover.

| Generador de ozono | GM1-E | GM3-E | GM7-E |

| Chamber volume | < 250 m3 | < 500 m3 | < 1.750 m3 |

| ozone production | 1 gO3/h | 3 gO3/h | 7 gO3/h |

| Caudal de aire | 15 lpm | 15 lpm | 50 lpm |

| Applied ozone rate | 200 gO3/h | 200 gO3/h | 200 gO3/h |

| Consumo | 80 W | 130 W | 160 W |

| Tamaño A x B x C | 200 gO3/h | 200 gO3/h | 200 gO3/h |

| Tamaño | 200 gO3/h | 200 gO3/h | 200 gO3/h |

Description

With air-cooled borosilicate dielectric ozone generation technology. To work in normal conditions of room temperature 5-35°C and Relative Humidity <80%, with a maximum of 12 hours of work per day.

All models are connected to 230v, 50 hz and have an ozone outlet for an 8mm Ext tube. The size is less than 40 x 30 x 22 cm.

Design and control

ZonoSistem has designed a modular ozone system for the disinfection of cold rooms with ozone.

With time programmer and CAP or PLC touch screen. Optionally, you can purchase the CRTL.SM41.B ozone sensor, for automatic control of ozone in the chamber.

Examples of ozone in refrigerated cameras and multi-chambers

Ozone in a multi-storage cold room for stone fruits in Terre de Crau, France.

Ozone in cold storage for cut flowers in Chipiona, Spain.

Ozone in cold room and fermentation room, pandera industry in Cádiz, Spain.

Ozone in cold storage for moss verdissimo. Valencia, Spain.

Ozone in cold room and cutting room in meat industry, Spain.

Ozone for environmental disinfection of dairy rooms in Lugo, Spain.